Ipris-Profil Plant – production of racks, paternosters, expositors, mesh containers, roll containers and tubes

Factory Ipris-Profil, founded in 2003 for more than 20 years has been designing and manufacturing finished metal products such as:

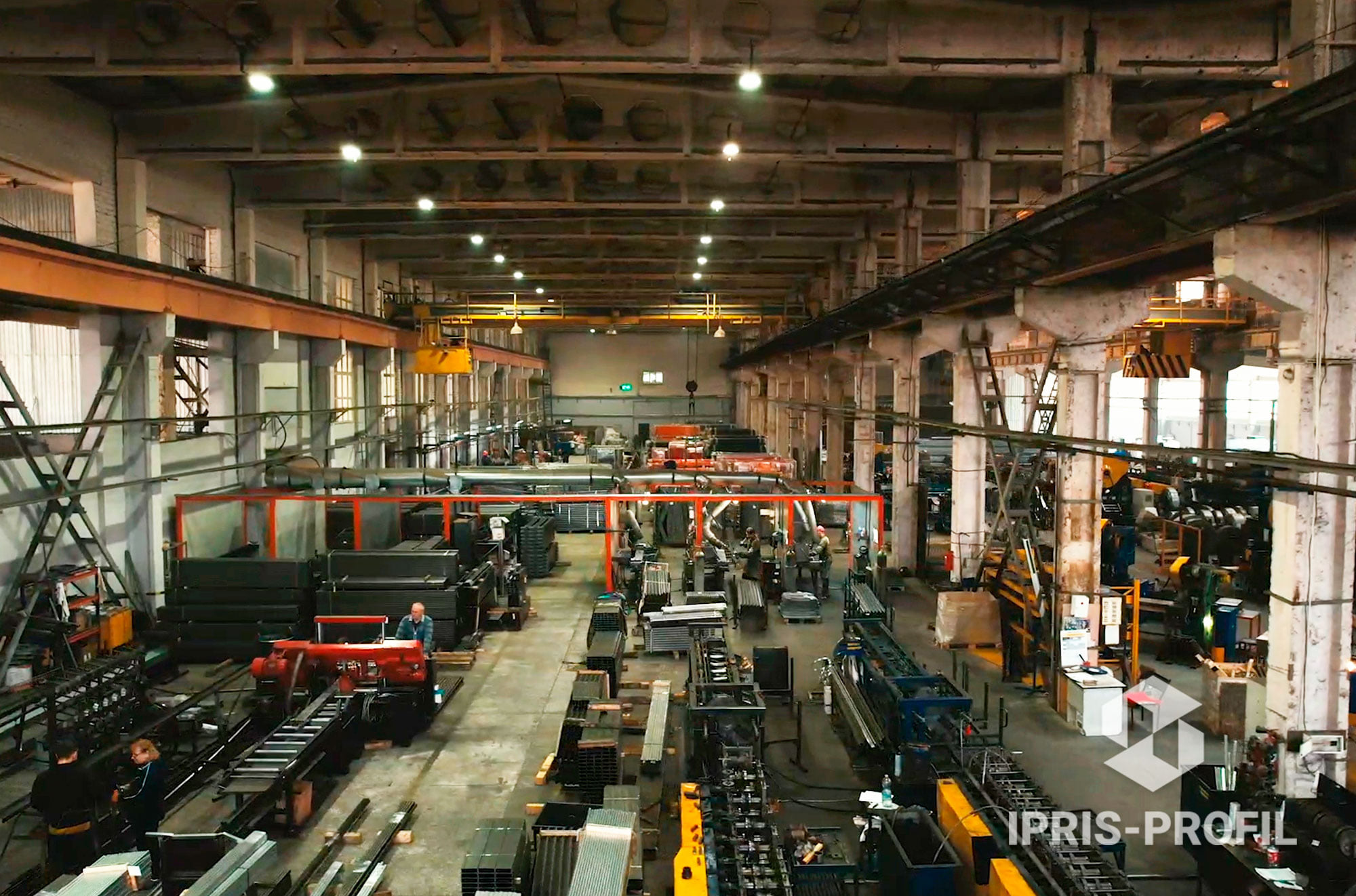

The capacity of the plant is located in the industrial zone of Kharkov on more than 35 000 m².

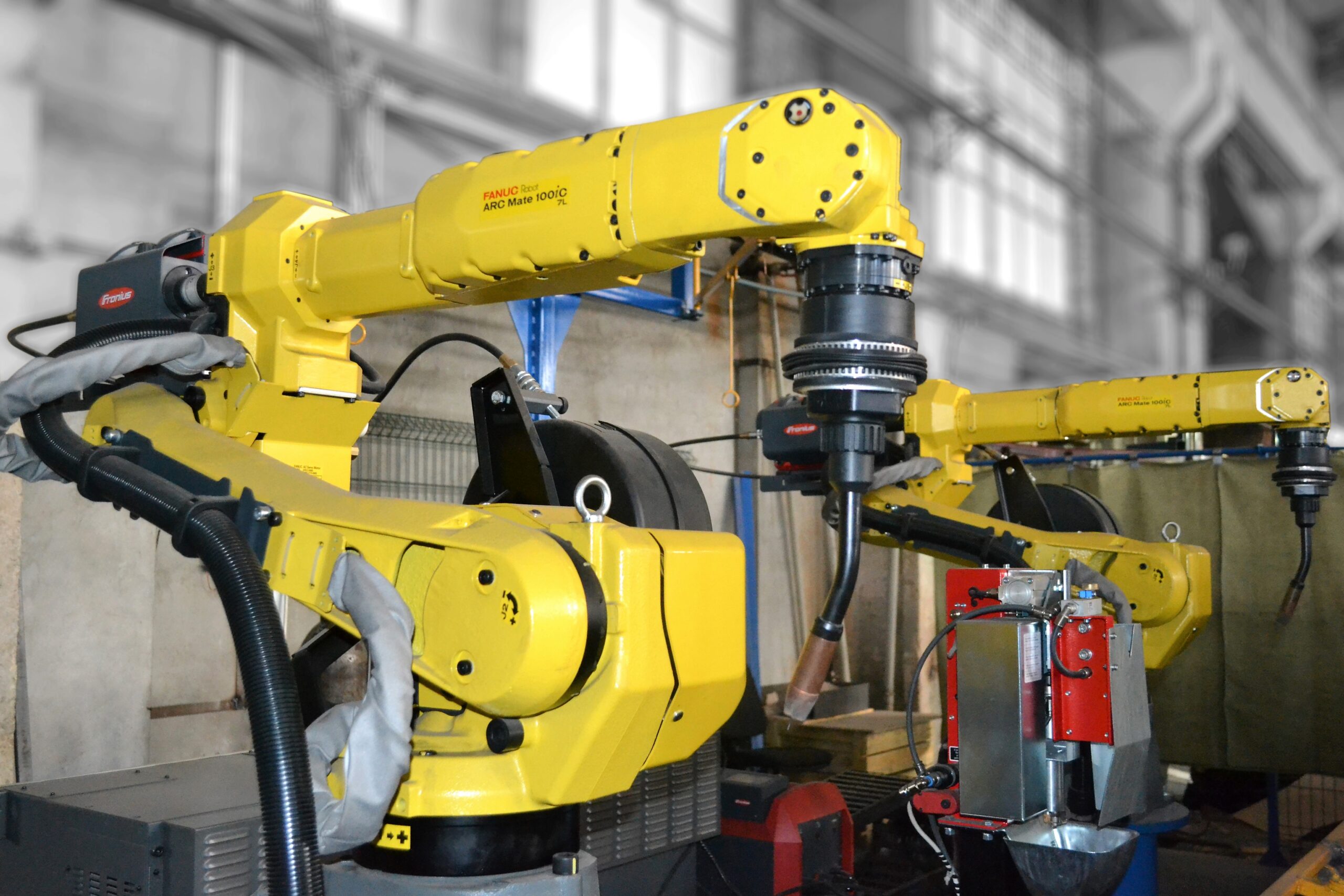

The company has a tool shop for the development and manufacture of tools and dies of any complexity; designs and uses its own high-precision profile bending equipment, lines for the production of perforated profiles, lines for the dissolution and cutting of metal, as well as uses equipment from leading manufacturers of the world:

- CNC pipe benders TM ADDISON;

- CNC sheet benders;

- robotic welding complex TM FANUC;

- laser cutting equipment.

Our customers will always have an advantage, because the production of Ipris-Profil products is carried out at personal facilities with the involvement of sites:

- metal cutting,

- machining,

- profiling,

- stamping and punching,

- welding section of production,

- as well as a conveyor-type powder coating area for industrial-scale painting or zinc coating on our own galvanizing lines.

The production of goods will always compare favorably in terms of price with competitors, as the construction of, for example, tire racks and roll containers is based on the use of thin-walled tubes of our own manufacture. This makes the production of Ipris-Profil a unique enterprise, which by the sign of economic purpose of products belongs simultaneously to industrial enterprises of class “A” and “B”.

The continuous improvement of production, constant forward movement, introduction of new equipment and technologies have allowed our company to increase the share of the domestic market from year to year and successfully promote our products on the world markets. We sell our products to more than 20 countries and carefully monitor changes and trends in intra logistics and fulfillment

STAGES OF PRODUCTION OF METAL RACKS, PROFILE TUBES, ROLL CONTAINERS, PATERNOSTERS AND CARTS INCLUDE:

1

order formation

2

design and technological preparation of production

3

realization of the production task

4

delivery and after-sales service

The metal warehouse is constantly replenished in order to shorten the production time and to ship the goods to the customer as soon as possible.

For finished products, the factory has organized a warehouse with safe storage of goods on padded pallet racks.

Production facilities

Quality management

Ipris-Profil has been operating in the ISO 9001 quality management system since 2008 and annually confirms compliance with the standards for customer orientation, continuous improvement, employee involvement, systematic approach to management, mutually beneficial relationships with suppliers, etc.

Implementation of the quality system in the technical control department (QC) requires from employees high qualification in performing works related to control of conformity of purchased products and materials and rejection of substandard products, as well as quality control functions of finished products.

All our products and components have certificates of conformity and are tested. Ipris-Profil experts monitor compliance with state standards and technical specifications, as well as control compliance with design documentation in the production of shelving. Reliability and quality for us – in the first place!

At the stage of acceptance of goods the customer is provided with a product passport, which specifies the main characteristics of the product, storage and transportation conditions.

Our product portfolio contains a wide range of goods, but in the field of intralogistics it is important for the manufacturer to go hand in hand with the customer and develop new technological solutions in addition to providing complex solutions for equipping the premises with racking systems, roll containers, warehouse carts and order picking carts. So, if you don’t find a product that fits your needs, we will develop an unrivaled solution for your business and turn your idea into a tangible reality.

After all, behind every strong brand is a strong manufacturer!

Advantage of Ipris-Profil – manufacturer of racks and tubes

Ipris-Profil Company is a unique enterprise – manufacturer in the Ukrainian market, because on the basis of economic purpose of the products belongs simultaneously to industrial enterprises of class “A” and class “B”.

Ipris-Profil has its own production of profile bending equipment, lines for the production of perforated profiles, lines of metal cutting and slitting, on which it manufactures racks, roll containers, electric-welded pipes, vine supports, etc. products.

What does it give our customers?

Technical inspection of rolling equipment and replacement of worn out parts is carried out in normal mode without stopping production.

You will receive the goods on time.

Own tool shop develops and manufactures tools and dies of any complexity.

Ability to quickly reconfigure the equipment for the production of other types of products and expansion of the range.

We accept in production individual orders according to customer’s specifications.

The powder coating section is equipped with an automatic line of conveyor type. This makes it possible to paint products on an industrial scale and the ability to choose any color from the RAL palette for our customers.

In addition to the equipment of our own production we use the equipment of leading manufacturers of the world:

All this together with a team of professionals allows us to produce quality products (pipes) and metal structures of increased complexity (racks, roll containers) in a short time.

Product development

The design and technological department of Ipris-Profil LLC, which has 20 years of experience in the development of equipment for equipping warehouses and retail premises, provides a range of services including:

- designing of trade equipment for different groups of goods;

- selection of racking structures with the necessary characteristics for equipping warehouses;

- site visit for measurements in case there are supporting columns, beams and other features of the room, which should be taken into account when creating the project;

- creation of flowcharts for the arrangement of storage systems, etc.

Since December 1, 2015 we with our partners offer the whole range of services related to the technology of creating construction supermarkets, including:

- technical task, planting of the shopping center on the plot of any configuration;

- technical assignment, placement of administrative and utility complex, reception, pre-sale preparation of goods, as well as parking lots;

- definition of assortment at the level of commodity groups;

- determination of the movement of commodity and customer flows;

- determination of the neighborhood of departments and commodity groups;

- technological plan of arrangement of trade equipment location of lighting branches;

- selection of presentation of goods and equipment for them;

- structure of service personnel;

- technical parameters and the necessary amount of loading and unloading equipment;

- design of the sales area, advertising products, navigation for customers;

- facade design;

- 3D visualization.